The creation of a masterpiece

Watchmaking

The only Swiss watch born out of technical engineering

New technologies

By encorporating technologies from medical and machine engineering, Max Twelve have pioneered new, never seen before technologies in the watch-making sphere.

Hand-finished

Made in Switzerland, designed in Zürich, and assembled in its own watch atelier. Every watch is unique, hand-finished, and made to order.

Freedom of creation

By being an independent brand, Max Twelve is free to innovate and will never be held back by bureaucracy and corporate limitations.

The making of a max twelve

A Max Twelve is Born

A Max Twelve is designed using modern SolidWorks 3D-CAD software. Once approved, the components are manufactured with high-precision machinery in the Swiss engineering industry and stored in the Max Twelve atelier.

Upon order, assembly is carried out in single-piece production across twelve defined and documented steps. One crucial step, requiring great precision and dexterity, is the installation of the hands.

The making of a max twelve

Laser-Cut and Oxidized TITANIUM Dials

Max Twelve is a pioneer in applying this technology to the watch industry. The dial is cut using precision laser technology, allowing for extremely complex shapes.

The titanium dial is then hand-ground, creating a unique surface pattern. Next, it undergoes anodization (oxidation) in a water bath by applying an electrical voltage. Max Twelve has perfected this process at the highest level, utilizing technology derived from the medical industry.

The making of a max twelve

Diamond-Like Precision

Have you ever seen a watch with sharp, precise edges like Max Twelve? Probably not.

Why? Because most watches are die-cut and pressed into shape. This process forces the material to flow, inevitably rounding the edges. But when the housing is CNC-milled from a solid block, it allows for sharp and extremely precise design - a hallmark of the Max Twelve designs.

For the final finish, each watch housing is meticulously hand-ground to preserve its sharp edges, with every surface finished in its own grinding direction.

Engineering excellence

The art of designing a product as simply as possible while achieving an optimal solution with minimal components.

At Max Twelve, the movement and dial mounts are directly milled into the case, eliminating the need for additional holding elements. This removes the conventional dial pins, which could break under shock loads.

Design and function go hand in hand—evident in the six Torx screws and six sleeve nuts on the case back, which hold the case together like a sandwich. The Torx screws not only embody industrial design but also serve a crucial functional purpose.

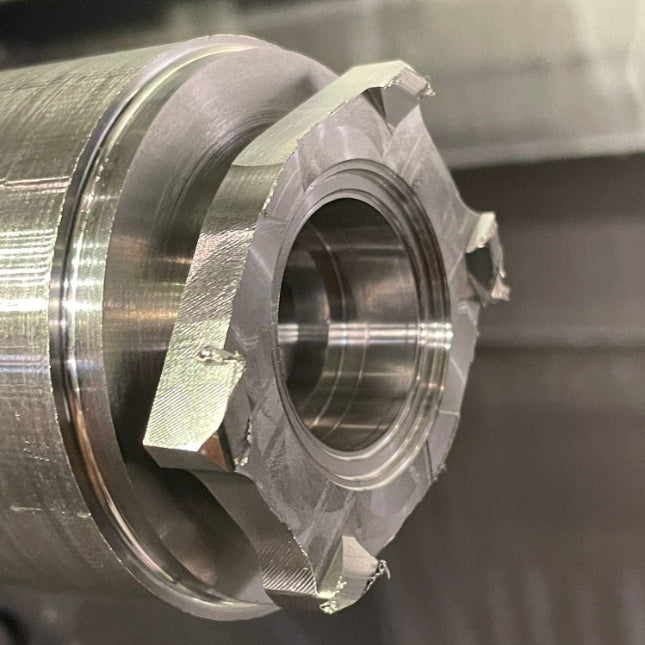

The principal of CNC turning

A subtracting manufacturing technology from mechanical engineering, by which the bezel and case back of Max Twelve watches are made

Introducing the Zurich workshop: by Founder Fabian Lehner

Max Twelve was founded with a vision: to bring the technologies of Swiss precision engineering into watchmaking, enabling people to express themselves through unique designs, high-quality materials, and rugged durability.

Get to know Max Twelve founder Fabian Lehner, Dipl. Ing. ETH, in the video below, as he guides you through a section of the Zurich-based watch workshop.

Questions about the watches?